Posted by Eduardo Munera

It's clear that Robot Interoperability has been a hot topic in the world of robotics, but do what does it mean? and how can it unravel the mass adoption of robotics fleets in real world applications?

Robot interoperability refers to the seamless collaboration and data exchange among diverse robotic systems, devices, and platforms, irrespective of their manufacturers, models, or designs. This concept aims for efficiency, scalability, and the continuous innovation of robotic applications. Nevertheless, there are important obstacles and problems to be solve before achieving these benefits. There are three major factors that have triggered the growing interest in interoperability:

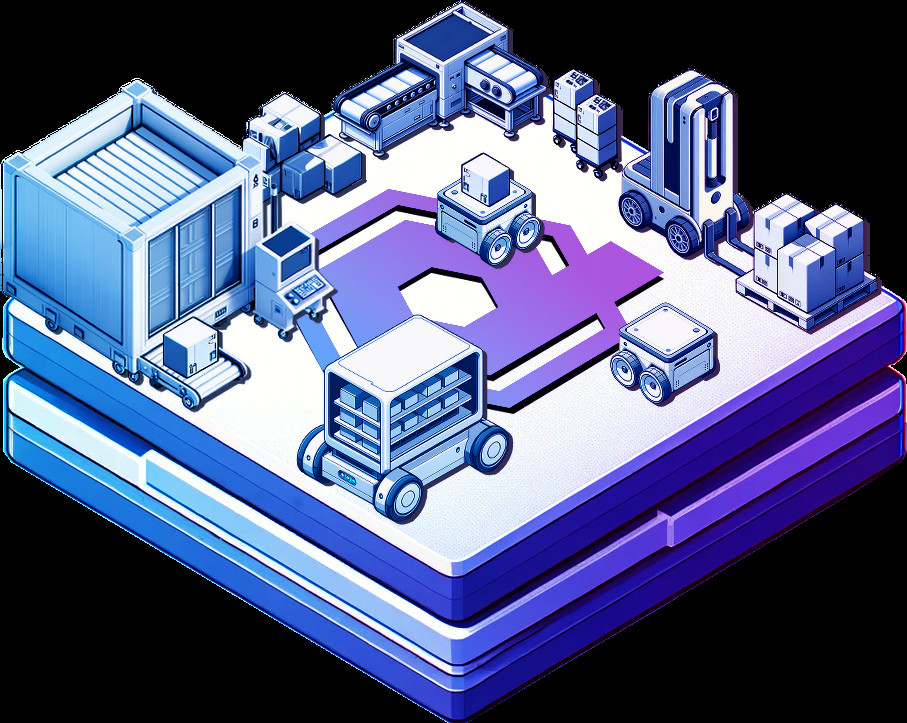

Growing Number of Robot Manufacturers

As of the writing of this article, there are over a thousand different robot manufacturers. The market saturation has pushed many of them to specialize in niche applications, achieving outstanding performance within a narrow scope. This context forces robot integrators to commit to multiple manufacturers in order to provide a comprehensive working solution. Seamlessly integrating and orchestrating a fleet of heterogeneous expert robots has become a significant part of deployment efforts.

Rise of Robot Fleet Systems

In the last 2-3 years, the clear need to orchestrate robot fleets has encouraged the emergence of companies focused on Fleet Management Systems (FMS). The approaches of different FMS may vary; some require robots to install their onboard controller, while others rely on software "adaptors" to interact with the robots. Their scope is also diverse, including device management, monitoring, teleoperation, traffic control, among other functions. Despite these initiatives, there is no mass adoption of any of these systems yet. As has happened with robotics manufacturers, niche FMS may soon emerge, focusing on different industry applications.

Integration Across Multiple Industries

In most applications, robots do not operate in isolation. Their interaction with the environment, humans, devices, and software systems is crucial for task execution. These interactions are domain-specific and exhibit a complexity inherent to the context of their performance. Achieving efficient operations requires a seamless integration of the robot fleet as part of the process. Therefore, it is key to understand that successful interoperability also requires addressing collaboration with contextual elements and processes.

Throughout this "Interoperability Series," we will delve into the challenges, solutions, standards, and much more, offering fresh insights to understand the current and future path of robot interoperability.

If you are interested in discovering how robot interoperability can benefit your business, reach out and let our team of experts guide you through the advantages for your company: Contact Us!