Posted by Eduardo Munera

Interoperability among robots, especially in industrial and service environments, is a paradigm aimed at optimizing efficiency, safety, and flexibility in automated operations. As we addressed in the previous article, "What's Robot Interoperability?", the ability of different robots to work together in increasingly intelligent and autonomous ways has become a key factor for operational success.

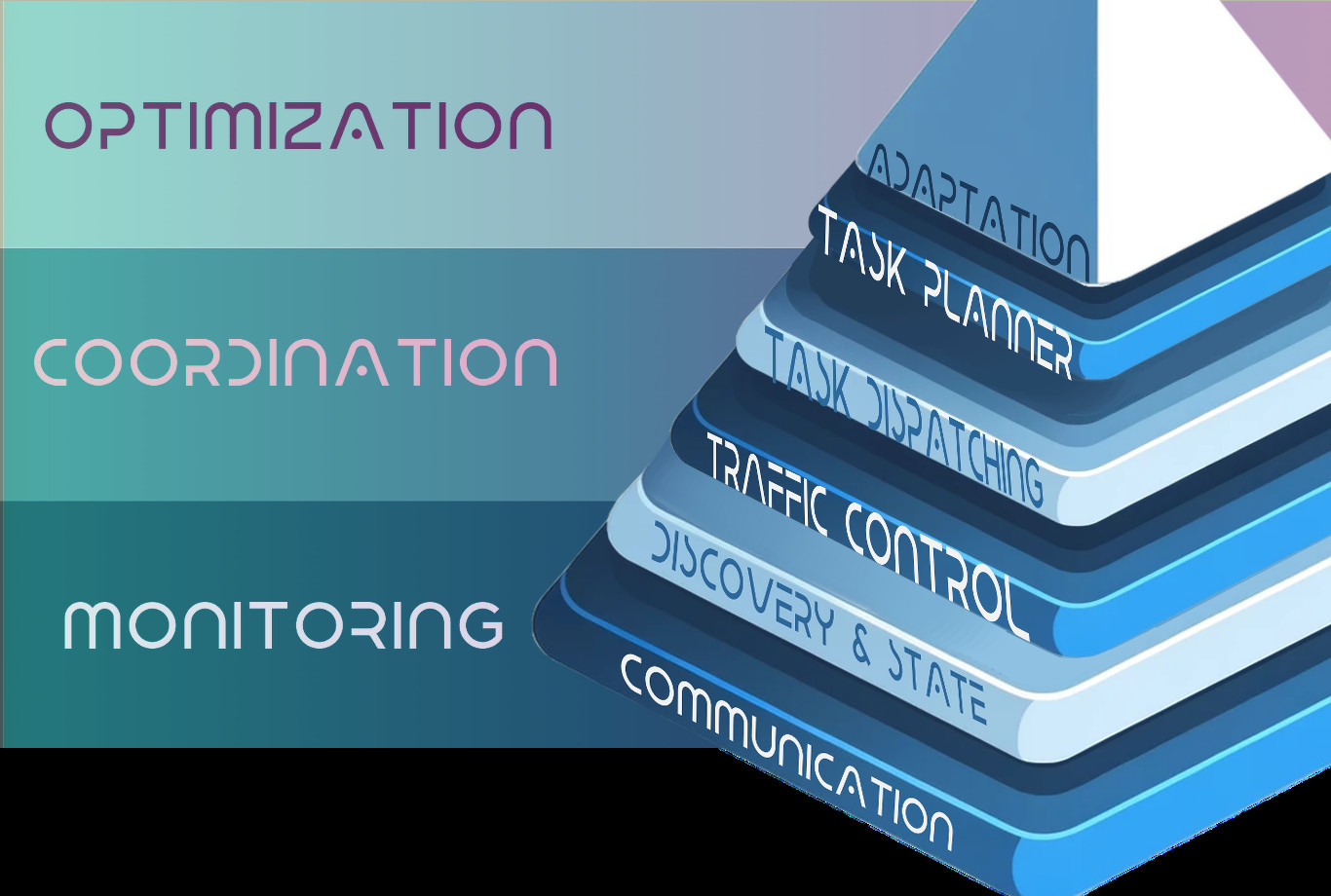

Although there are multiple initiatives to standardize robot communication, it is a fact that nowadays there is segmentation of robot APIs, allowing different degrees of control over the robots. This limitation will determine the scope of the orchestration. To simplify, three main levels of interoperability can be identified: Monitoring, Coordination, and Optimization.

Level 1: Monitoring

The first level of interoperability focuses on the ability of robots within a fleet to communicate with each other, exchanging relevant information. This level is essential for establishing a coordinated operational base.

To achieve this exchange, a communication channel must be established, and a protocol agreed upon. The scope of this protocol and its openness will determine the degree of integration amongst the members of the robot fleet.

The minimum requirement for establishing any kind of coordination is the ability to discover the available robots and their current state. This enables management systems and human operators to obtain operational information about the robot's condition, its performance, and potential issues in real-time.

Level 2: Coordination

The second level advances towards the effective coordination of robot operations. At this level, information about the state is not only exchanged, but instructions of varying complexity can also be shared, enabling robots to work on complementary or concurrent tasks in harmony.

The most fundamental form of coordination is traffic control, ensuring that the fleet's trajectories do not conflict, thus avoiding robot collisions and deadlocks. Advanced traffic control strategies may be utilized to adjust the fleet's navigation paths, optimizing the transportation workflow.

The next step in coordination is task dispatching and the capability to command different robots with specific tasks. Multiple dispatching policies can be implemented by considering parameters such as the robot's status and availability, its position, the priority of the tasks, or even manual assignment.

Level 3: Optimization

The third level represents the highest degree of interoperability, leading to better resource utilization, reducing downtime and maximizing productivity. Although it offers significant benefits, it also requires a degree of standardization and complexity that remains largely unachieved in the industry.

Optimization involves an advanced level of intelligent planning algorithms that reconfigure and reschedule the task execution plan in response to fluctuating demands and situations. This intelligent planning improves productivity and increases the flexibility and adaptability of the fleet.

A dynamic adaptation and forecasting mechanism enables the system not just to react to changing environmental conditions but also to anticipate them. At this level, systems are capable of constantly assessing the efficiency of operations and adjusting task allocations and routes in real time to achieve objectives more effectively.

Conclusion

Interoperability in robot fleets ranges from simple state monitoring to dynamic task optimization, reflecting a spectrum of increasing intelligence and orchestration. This journey towards greater interoperability not only expands the operational capabilities of robotic fleets but also opens up new opportunities for innovation in how robotic systems are designed, managed, and implemented across various sectors. The strategic implementation of these levels of interoperability promises to revolutionize the efficiency and effectiveness of automated operations in the near future.